Technical Description

1、 Material:

The upper formwork is made of Q235B carbon structural steel to ensure structural stability

The mold frame is made of Q355B high-strength structural steel to ensure the overall strength of the mold

The Lining and shoes are made of low-carbon alloy steel to ensure high hardness and wear resistance of the mold

2、 Heat treatment and hardness:

Use advanced multifunctional heat treatment furnaces. The entire heat treatment process is automatically controlled to ensure the quality and stability of the heat treatment. The Lining and shoes hardness HRC58-62. Depth of carburized layer ≥ 1.5mm

3、 Technological advantages:

The molds for road tiles such as pavement bricks, wave bricks, and hexagonal bricks are processed using a whole piece of steel wire cutting method to ensure sufficient strength of the molds during the use of strong vibration force by the brick machine. High precision assembly technology is used to process molds such as curbstones and blocks for high-quality products, ensuring smooth demolding of high concrete products.

4、 Technical parameters:

4.1 Road tiles:

4.1.1 Unilateral clearance between presser foot and mold cavity: 0.2 mm ≤ Unilateral clearance ≤ 0.4mm

4.1.2 Flatness of the whole board: ≤ 0.5mm

4.1.3 Deviation in length and width dimensions of a single cavity model: -0.3 to+0.3mm

The dimensional deviation of the height (filling depth) of the lower model cavity is ± 0.5mm

4.1.5 The width and height dimensions of the chamfer on the molded foot are as shown in the diagram, with a deviation of ± 0.2mm

4.1.6 Single side draft angle: product demolding is unobstructed

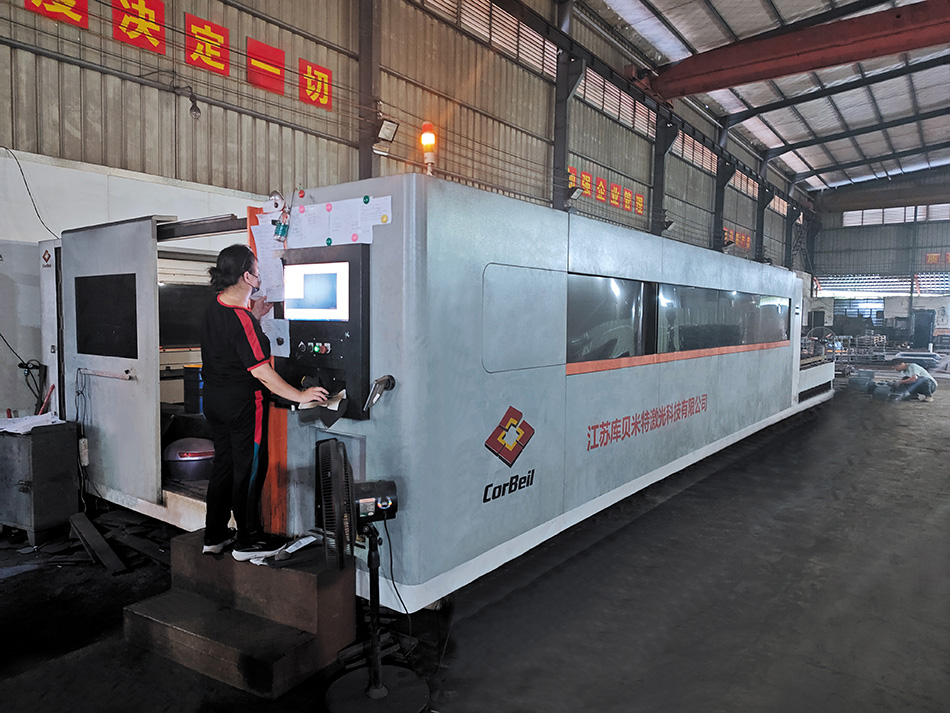

5、 Excellent processing equipment ensures the accuracy of mechanical processing:

See processing equipment for details

Equripment

Heat treatment equipment

Design and Inspection